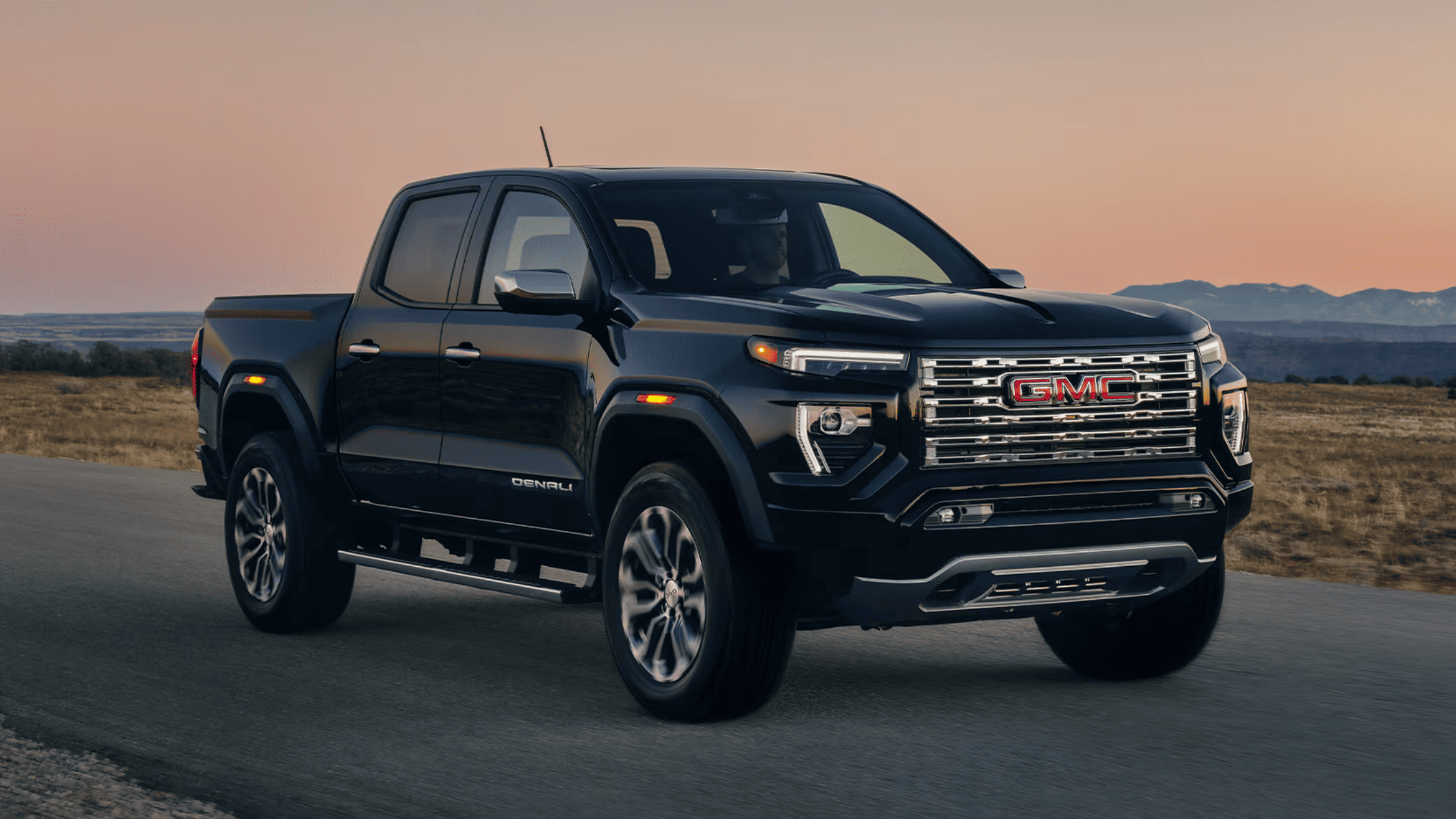

2026 GMC Canyon Denali near Morganton, NC

The 2026 GMC Canyon Denali represents a focused application of mid-size truck engineering built around controlled power delivery, integrated digital systems, and comprehensive driver-assistance technology. This model is configured to deliver consistent performance across commuting, trailering, and extended driving scenarios through a unified platform that emphasizes mechanical efficiency and system integration. The Denali trim builds upon the Canyon architecture by incorporating higher-grade materials, expanded digital interfaces, and additional monitoring technologies without altering the vehicle’s dimensional footprint or utility-focused layout.

Every major component of the 2026 GMC Canyon Denali is calibrated to support stability, durability, and predictable response. Engine output, chassis design, drivetrain tuning, and electronic systems operate within defined parameters to maintain consistency across varying loads and driving environments. The result is a mid-size truck that maintains a controlled operating profile while integrating modern vehicle technology and advanced safety systems.

TurboMax™ Powertrain Configuration and Output Characteristics

The 2026 GMC Canyon Denali is equipped with a standard TurboMax™ 2.7-liter turbocharged gasoline engine. This engine produces 310 horsepower and 430 pound-feet of torque, providing a high torque output relative to engine displacement. The turbocharged configuration is designed to deliver torque early in the rev range, supporting steady acceleration and sustained pulling force under load.

Power is routed through an automatic transmission that is tuned to maintain smooth gear transitions while managing torque delivery during towing and grade changes. Transmission programming prioritizes gear stability and controlled downshifts to reduce unnecessary engine speed fluctuations. This configuration supports a maximum towing capability of up to 7,700 pounds when properly equipped, aligning engine output with structural and braking capacity.

Selectable drive modes allow the vehicle’s throttle response, transmission behavior, and traction systems to adapt to specific driving conditions. These modes adjust electronic parameters rather than mechanical components, ensuring consistency while accommodating changes in road surface or terrain.

Exterior Systems and Functional Design Integration

The exterior of the 2026 GMC Canyon Denali is designed with an emphasis on structural alignment and aerodynamic efficiency. Body panel geometry contributes to airflow management while preserving the proportions necessary for cargo and trailering utility. The grille and front fascia are engineered to support engine cooling requirements while maintaining consistent airflow distribution across the radiator and intercooler.

LED exterior lighting systems provide consistent illumination across varying visibility conditions. Headlamp and taillamp assemblies are designed to deliver uniform light distribution while supporting long service life. Lighting placement enhances visibility without interfering with airflow or structural elements.

The cargo bed is reinforced to support equipment transport and payload stability. Integrated tie-down points and structural bracing maintain load security during acceleration and braking. Bed dimensions and wall construction align with standard cargo management requirements without reducing maneuverability.

Structural Platform and Suspension Engineering

The 2026 GMC Canyon Denali is constructed on a reinforced frame designed to balance torsional rigidity with ride compliance. Frame geometry supports both load-bearing requirements and vibration management, contributing to predictable handling under various driving conditions. Suspension components are tuned to manage weight transfer during acceleration, braking, and cornering while maintaining ride stability.

Front and rear suspension systems are engineered to absorb road irregularities without compromising steering precision. Damping rates are selected to support vehicle control during trailering operations and uneven surface travel. The suspension setup contributes directly to tire contact stability, which supports braking performance and lateral control.

Steering calibration emphasizes linear input response, allowing precise maneuvering in confined environments such as parking areas while maintaining directional stability at highway speeds.

Cabin Architecture and Material Engineering

The interior of the 2026 GMC Canyon Denali is structured around driver visibility, ergonomic access, and material durability. Seating surfaces and trim components are selected for resistance to wear while maintaining consistent tactile response over extended use. The seating structure supports proper posture and weight distribution, contributing to reduced fatigue during longer driving periods.

Control placement follows a functional layout that minimizes reach distance and visual diversion. Switchgear and interface components are designed for consistent resistance and tactile feedback. Acoustic insulation and structural damping materials reduce intrusion from road and drivetrain noise, supporting a controlled cabin environment.

Rear seating maintains proportional legroom and headroom relative to the vehicle’s size classification. Interior storage areas are integrated into the cabin structure to support daily utility without compromising passenger space.

Digital Instrumentation and Infotainment Architecture

The 2026 GMC Canyon Denali incorporates an 11.3-inch center touchscreen display paired with a digital driver information cluster. These displays present vehicle data, navigation interfaces, and system controls through a unified graphical environment. Display resolution and refresh rates are calibrated to maintain clarity under varying lighting conditions.

The infotainment system supports smartphone integration and voice-command functionality, allowing drivers to access navigation, communication, and media systems without manual input. System menus are structured to reduce navigation steps and maintain consistent control logic across functions.

Software architecture supports system updates through integrated connectivity features, allowing the vehicle’s digital systems to maintain compatibility with evolving software standards over time.

Camera Integration and Visual Monitoring Systems

The 2026 GMC Canyon Denali offers an available camera system that provides up to ten selectable views. These views include forward-facing, rear-facing, surround, and underbody perspectives. Underbody cameras allow the driver to monitor terrain beneath the vehicle, supporting navigation across uneven surfaces and confined spaces.

Camera feeds are displayed through the central touchscreen, with selectable overlays that assist with alignment and spatial orientation. These systems are integrated into the vehicle’s electronic architecture, allowing coordinated operation with parking assistance and trailering technologies.

Visual monitoring systems enhance driver awareness during low-speed maneuvering, trailering alignment, and surface navigation without altering mechanical operation.

Safety Architecture and Driver-Assistance Technology

Safety systems in the 2026 GMC Canyon Denali are organized into layered monitoring and response technologies. The Pro Safety and Canyon Safety Plus systems incorporate sensors, cameras, and control modules that monitor vehicle surroundings and driver input.

These systems provide alerts and automated responses designed to reduce collision risk during forward travel, lane transitions, and low-speed maneuvers. Automated braking and steering assistance functions operate within defined thresholds to support driver control without abrupt intervention.

Structural safety is supported through energy-absorbing zones and reinforced cabin architecture. These elements are engineered to manage impact forces while maintaining occupant compartment integrity.

Trailering Support and Operational Monitoring

Trailering technology in the 2026 GMC Canyon Denali integrates digital monitoring tools that assist with hitch alignment, load stability, and vehicle response under tow. Visual guidance systems support trailer connection, while electronic stability controls manage sway and braking input during movement.

Integrated trailering interfaces allow drivers to monitor vehicle and trailer status through the central display. These systems operate in coordination with the drivetrain and braking systems to maintain consistent performance during towing operations.

Trailering support technologies are designed to function without altering driver input requirements, maintaining consistent control logic across operating conditions.

Schedule a Test Ride at Elevation Chevrolet GMC

Drivers interested in examining the technical integration of the 2026 GMC Canyon Denali can schedule a test drive through Elevation Chevrolet GMC near Morganton, NC. A scheduled evaluation allows direct interaction with the TurboMax™ engine response, digital display systems, and driver-assistance technologies under controlled conditions. Experiencing the steering calibration, cabin ergonomics, and visibility systems during normal driving provides measurable insight into vehicle operation. A test drive also enables assessment of suspension behavior and power delivery consistency across varied speeds. Appointments can be arranged to ensure sufficient time for system evaluation without interruption.